Industry Trends

The role of adhesives in industry is changing. What used to be regarded as a secondary or “auxiliary” material is now recognized as an enabling technology. The way manufacturers design, assemble, and maintain products is evolving, and bonding is at the center of many of these changes.

From Welding and Fasteners to Bonded Structures

As industries pursue lighter, more efficient, and more complex structures, traditional methods such as welding and mechanical fastening show their limitations. They can introduce stress concentrations, heat-affected zones, cosmetic issues, and constraints on design freedom.

Structural bonding, when properly designed and validated, allows load to be distributed more evenly and enables the joining of dissimilar materials without damaging them. This is particularly valuable in automotive, transportation, and architectural applications, where metals must be combined with plastics, composites, or glass.

QinanX continuously develops and refines structural adhesives—epoxy, acrylic, modified polyurethane, silicone-based systems—aimed at these new design approaches. We view adhesive selection, joint geometry, and process control as a single system that must be optimized together.

Safety, Health, and Environmental Responsibility

Regulatory frameworks around chemicals, emissions, and workplace safety are becoming more stringent worldwide. At the same time, end users and brand owners are increasingly attentive to the environmental and health implications of materials used in their products and buildings.

For adhesive and sealant systems, this means a careful balance between performance and environmental profile. Low odor, low VOC content, and the absence of certain substances are not only regulatory concerns, but also influence user and installer acceptance.

QinanX integrates health, safety, and environmental considerations into our product design and documentation. We support customers in understanding what stands behind each technical choice: not only whether an adhesive is “strong enough”, but also how it fits into regulations, standards, and sustainability objectives over the product’s entire life.

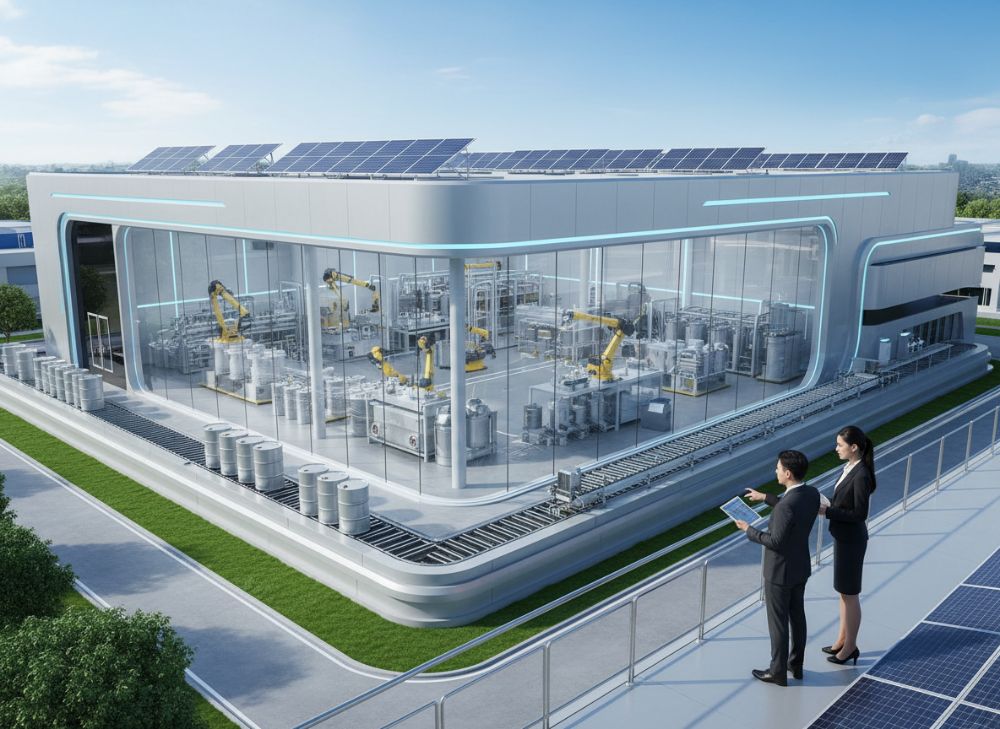

Automation and Data in Bonding Processes

Bonding processes are increasingly handled by automated equipment. Robotic arms, meter-mix dispensers, and monitoring systems are becoming part of everyday production, even in medium-sized factories. This imposes new demands on adhesives: consistent rheology from batch to batch, predictable open time and cure, and compatibility with specific dispensing technologies.

At the same time, manufacturers are collecting more process data and using it to stabilize and improve quality. In such an environment, the adhesive is not an isolated product but a component in a controlled, measurable process.

QinanX formulates with automation in mind, and supports customers in defining suitable process windows and control points. Our goal is that adhesives should not be a “black box”, but a well-understood, manageable element in automated lines.

From Product Supply to Technical Partnership

More manufacturers now expect adhesive suppliers to be long-term partners rather than simple product vendors. They want support from the concept stage, participation in design reviews, joint testing and validation, and responsive assistance when field issues arise.

QinanX has shaped its service model around these expectations. We are prepared to act as a co-developer, to share data and analyses, and to update formulations or processes when new requirements emerge. This type of collaboration benefits both sides: customers can rely on deeper expertise, and we gain a sharper understanding of real-world needs to guide our innovation.

Sharing Knowledge and Building Confidence

As bonding technologies become more sophisticated, engineers, buyers, and installers want greater transparency. They wish to understand why one type of adhesive is chosen over another, what limits must be respected, and how failures can be prevented rather than merely repaired.

To answer these needs, QinanX invests in clear, practical technical communication. We are willing to explain the principles behind our recommendations, the test methods we use, and the assumptions that underlie specific designs. By sharing knowledge rather than hiding it, we help our customers make informed decisions and build a more reliable bonding culture within their own organizations.