Industry Solutions

Tailored Adhesive Systems for Different Industries and Processes

Industrial bonding is never “one formula fits all”. Different substrates, production speeds, environments, and regulatory requirements demand application-specific adhesive systems. Qingdao QinanX New Material Technology Co., Ltd offers industry-focused solutions that combine:

Below is an overview of key industries we serve and how our adhesive technologies support each segment.

Automotive & Transportation Solutions

Automotive and transportation components must withstand vibration, shock, chemicals, and extreme temperature cycles over long service lives.

Our adhesive solutions help OEMs and Tier suppliers replace mechanical fastening, improve NVH performance, and reduce assembly complexity.

Typical applications:

Recommended product & technologies

Performance advantages

Value for customers

Construction & Building Materials Solutions

In construction and building materials, adhesives must deliver durability, weather resistance, safety, and aesthetics over many years.

QinanX provides solutions both for on-site construction and factory-prefabricated systems.

Typical applications:

Recommended product & technologies

Performance advantages

Value for customers

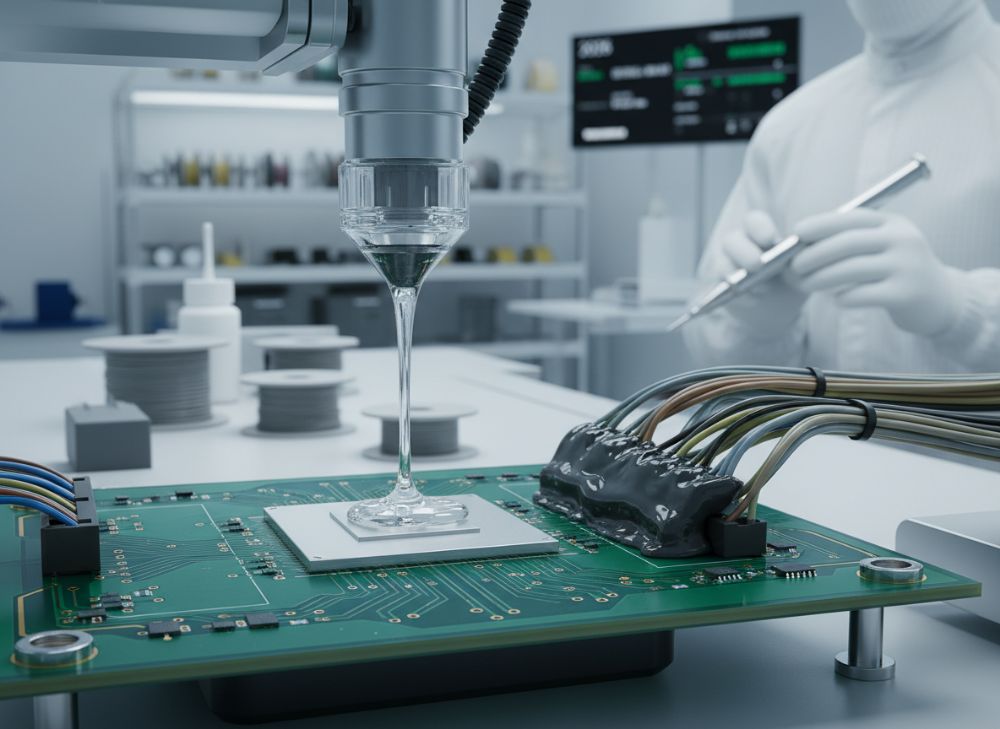

Electronics & Electrical Component Solutions

Electronics manufacturing demands precision, clean processing, and high reliability under thermal and electrical stress.

QinanX supports electronics OEMs and EMS providers with formulations tailored to their processes and board designs.

Typical applications:

Recommended product & technologies

Performance advantages

Value for customers

Packaging & Labeling Solutions

Packaging and labeling lines operate at high speed, where every second of curing time and every gram of adhesive affects cost and efficiency.

QinanX provides formulations that balance adhesion, speed, cost, and appearance.

Typical applications:

Recommended product & technologies

Performance advantages

Value for customers

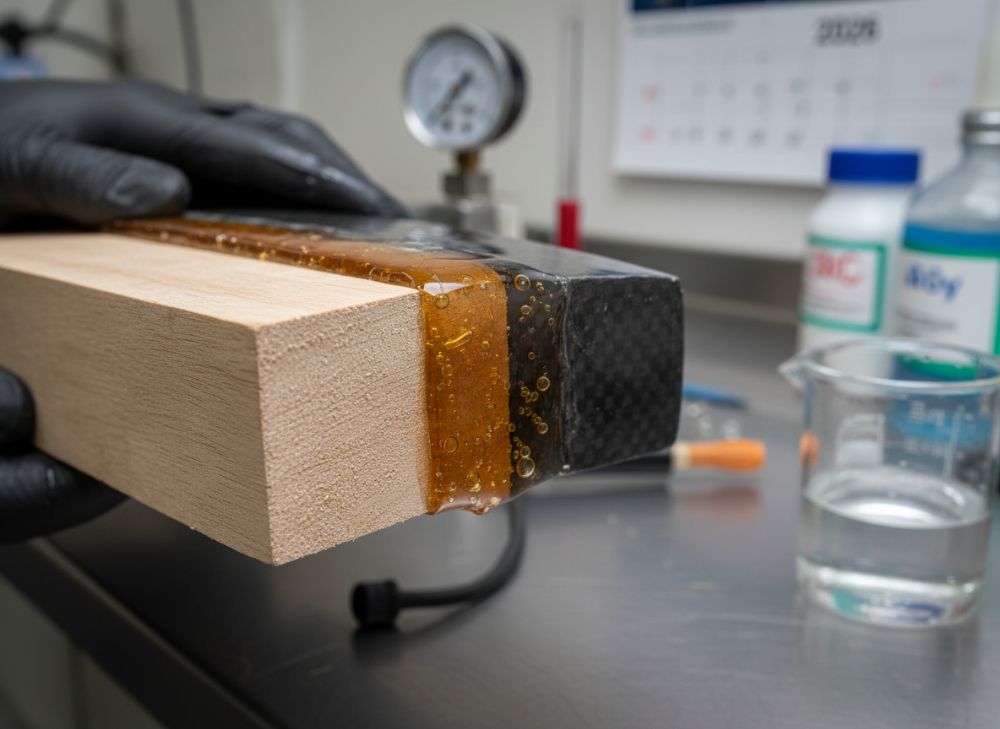

Furniture & Woodworking Solutions

In furniture and woodworking, adhesives must deliver structural strength, aesthetic quality, and process efficiency.

Our solutions serve both mass furniture production and customized, high-value woodworking.

Typical applications:

Recommended product & technologies

Performance advantages

Value for customers

General Industrial & OEM Solutions

Beyond these sectors, Qingdao QinanX supports a wide range of general industrial and OEM applications:

We offer:

Need a solution for a special application?

Our technical team can analyze your substrates, operating conditions, and process constraints, then propose targeted formulas and testing plans.