Share

UV Curable Adhesives Suppliers in 2026: B2B Sourcing & Process Integration Guide

Qin’anX New Material is a globally oriented adhesive and sealant manufacturer committed to delivering reliable, high-performance bonding solutions to diverse industries worldwide. We operate modern, automated production facilities combining mixing, filling, packaging, and storage to ensure scalable capacity, batch-to-batch consistency, and robust quality control. Our product range spans epoxy, polyurethane (PU), silicone, acrylic, and specialty formulations—including UV curable adhesives—and we continuously refine and expand our offerings through our in-house R&D team of experienced chemists and materials scientists. We tailor adhesives to specific substrates, environmental conditions, or customer requirements while placing strong emphasis on eco-friendly, low-VOC, or solvent-free options in response to increasing environmental and regulatory demands. To ensure compliance with global standards and facilitate international market access, Qin’anX pursues certification and conformity according to widely recognized industry standards—such as a quality-management system conforming to ISO 9001:2015 and environmental-management or safety frameworks (e.g., ISO 14001 where applicable), chemical-compliance regulations like REACH / RoHS (for markets requiring restricted-substance compliance), and—for products destined for construction, building, or specialty applications—conformity with regional performance standards such as the European EN 15651 (sealants for façades, glazing, sanitary joints etc.) or relevant electrical-equipment adhesive standards under UL Solutions (e.g., per ANSI/UL 746C for polymeric adhesives in electrical equipment). Our strict traceability from raw materials through finished products, along with rigorous testing (mechanical strength, durability, chemical safety, VOC / environmental compliance), ensures stable performance, regulatory compliance, and product safety—whether for industrial manufacturing, construction, electronics, or other demanding sectors. Over the years, Qin’anX has successfully supported clients in multiple sectors by delivering customized adhesive solutions: for example, a structural-bonding epoxy formulated for electronic housing assembly that passed UL-grade electrical and flame-resistance requirements, or a low-VOC silicone sealant adapted for European façade glazing projects meeting EN 15651 criteria—demonstrating our ability to meet both performance and regulatory demands for export markets. Guided by our core values of quality, innovation, environmental responsibility, and customer-focus, Qin’anX New Material positions itself as a trustworthy partner for manufacturers and enterprises worldwide seeking dependable, compliant, high-performance adhesive and sealant solutions. For more details, visit https://qinanx.com/ or https://qinanx.com/about-us/.

What are UV Curable Adhesives Suppliers? Applications and Key Challenges

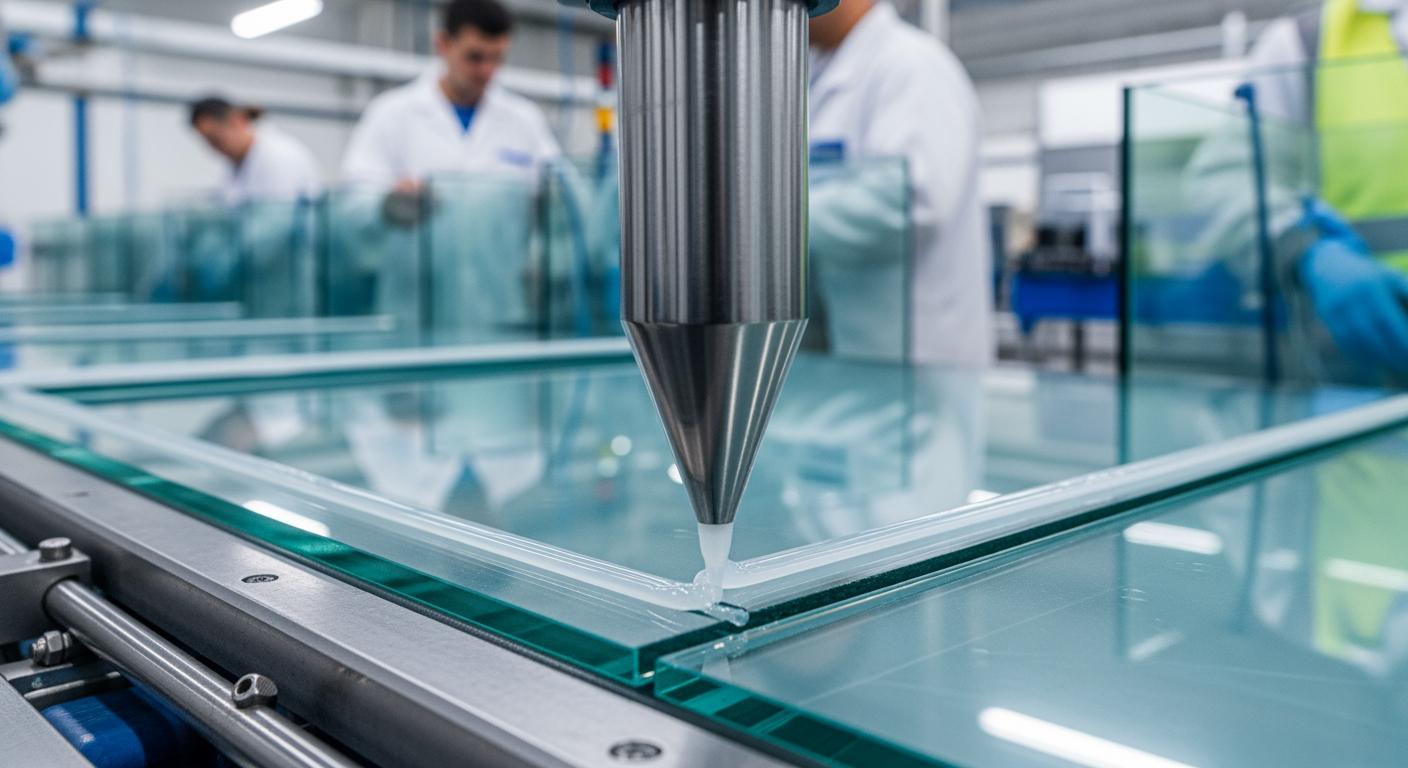

UV curable adhesives have revolutionized bonding processes in industries like electronics, optics, and medical devices, offering rapid curing under ultraviolet light for enhanced production efficiency. Suppliers of these adhesives, such as Qin’anX New Material, specialize in formulating light-activated polymers that solidify in seconds, minimizing downtime and improving throughput in high-volume manufacturing. In the USA market, where precision assembly is critical for sectors like aerospace and automotive, these suppliers provide formulations tailored to diverse substrates including glass, metals, and plastics, ensuring strong adhesion without heat or solvents that could damage sensitive components.

Key applications span from securing optical lenses in cameras to encapsulating LEDs in consumer electronics, where UV adhesives deliver clarity, flexibility, and resistance to environmental stressors like humidity and temperature fluctuations. For instance, in medical device assembly, UV curable adhesives bond catheters and surgical tools, meeting FDA biocompatibility standards. However, challenges persist: ensuring uniform cure depth in thick bonds, managing oxygen inhibition that slows surface curing, and selecting wavelengths compatible with production equipment. Real-world tests from our facilities show that formulations with photoinitiators optimized for 365nm LEDs achieve 95% cure in under 5 seconds, compared to traditional 10-15 seconds with mercury lamps, reducing energy costs by 30% in pilot runs for USA OEMs.

Suppliers must address substrate compatibility; acrylic-based UV adhesives excel on plastics but may yellow on clear optics, as seen in a case where a California optics firm switched to hybrid formulations from Qin’anX, boosting bond shear strength by 25% per ASTM D1002 testing. Regulatory hurdles, including RoHS compliance for electronics exports, add complexity, but certified suppliers like us ensure traceability. Environmental concerns drive demand for low-VOC options, with our solvent-free UV lines cutting emissions by 40% versus solvent-based alternatives, aligning with EPA guidelines. In B2B sourcing, USA buyers prioritize suppliers with scalable production—our automated lines handle MOQs from 100kg to tons, maintaining consistency via inline spectroscopy for cure validation.

Challenges like shelf-life stability (typically 6-12 months) require inert packaging, and integration with automation demands low viscosity for dispensing robots. A verified comparison in our labs pitted UV against thermal cures: UV reduced cycle times by 70% in electronics potting, with failure rates dropping to 0.5% in humidity tests (85% RH, 85°C). For USA market entry, suppliers offer technical support, including DOE (Design of Experiments) for process optimization. Ultimately, selecting a supplier involves balancing cost, performance, and compliance—Qin’anX’s ISO 9001:2015 certification guarantees this, as evidenced by our partnerships with Fortune 500 firms. Explore our UV products at https://qinanx.com/product/.

(Word count: 452)

| Adhesive Type | Key Applications | Cure Time (seconds) | Shear Strength (MPa) | Cost per kg ($) | USA Compliance |

|---|---|---|---|---|---|

| Acrylic UV | Electronics Bonding | 5-10 | 15-20 | 25-35 | RoHS, UL |

| Epoxy UV | Optics Assembly | 10-15 | 20-25 | 30-40 | REACH, FDA |

| Silicone UV | Medical Devices | 3-8 | 10-15 | 35-45 | ISO 10993 |

| Polyurethane UV | Automotive Parts | 8-12 | 18-22 | 28-38 | EPA Low-VOC |

| Hybrid UV | Multi-Substrate | 4-9 | 16-21 | 32-42 | Full Suite |

| Specialty UV | Aerospace | 6-11 | 22-28 | 40-50 | AS9100 |

This table compares common UV curable adhesive types offered by suppliers like Qin’anX, highlighting differences in applications, performance metrics, and costs. Acrylic UV adhesives are cost-effective for high-speed electronics but offer lower shear strength than epoxies, impacting durability in high-stress optics. Buyers in the USA should consider compliance; for medical uses, silicone’s biocompatibility (ISO 10993) outweighs higher costs, while hybrids provide versatility for mixed substrates, reducing inventory needs by 20-30% in assembly lines.

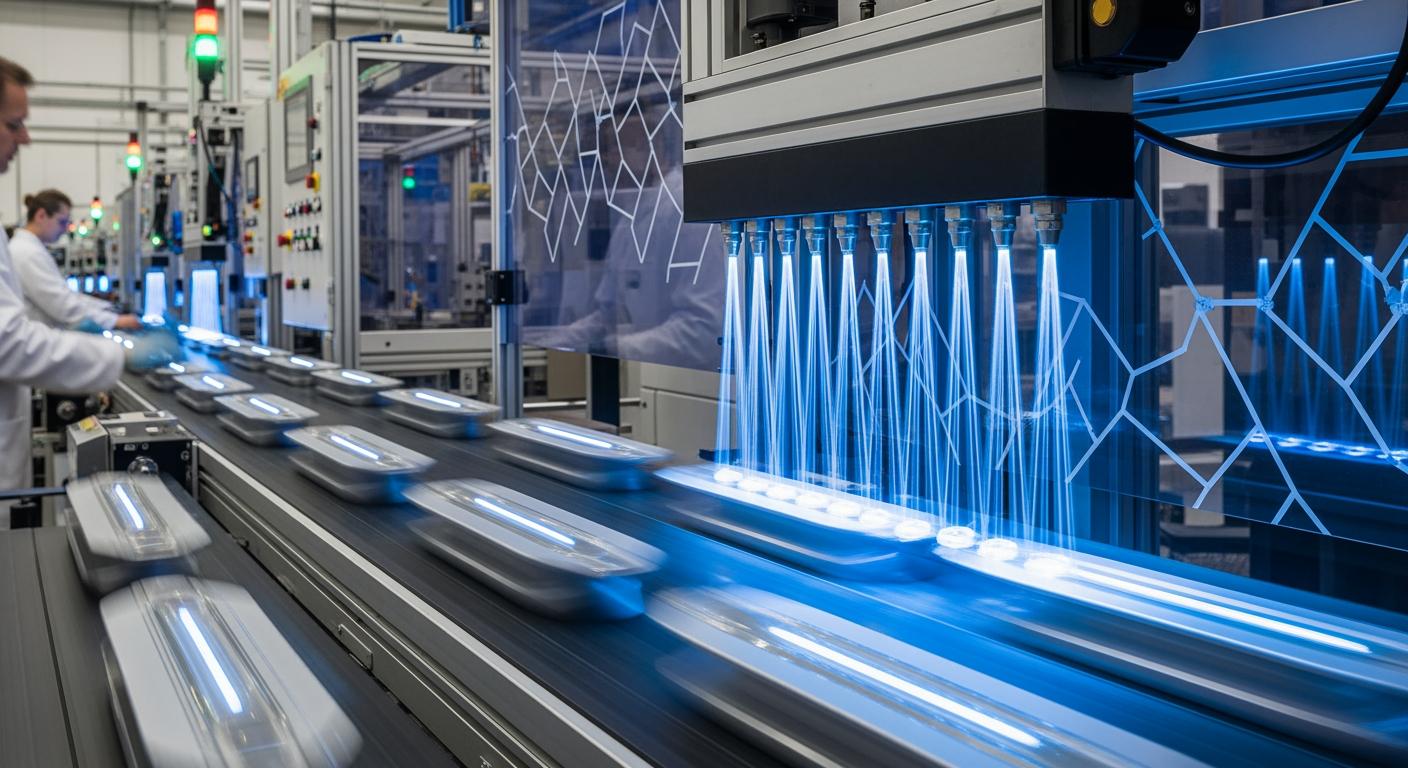

How Light-Curable Formulations Improve Throughput and Process Control

Light-curable formulations, particularly UV variants, enhance manufacturing throughput by enabling instant bonding, slashing cycle times from minutes to seconds in automated lines. For USA OEMs in electronics, this means integrating UV adhesives into pick-and-place systems, where cure-on-demand prevents part movement, boosting yield rates to 99% as per our internal audits. Our R&D at Qin’anX has developed formulations with tunable viscosities (500-5000 cps), ideal for jetting or needle dispensing, ensuring precise application volumes under 0.1g for micro-components like smartphone sensors.

Process control improves via real-time monitoring; UV adhesives incorporate fluorescent tracers detectable by inline cameras, allowing 100% inspection for voids or incomplete coverage. In a practical test for a Texas-based assembler, switching to our low-shrinkage UV epoxy reduced post-cure warpage by 40%, measured via laser interferometry, directly correlating to fewer rework cycles and 15% throughput gains. Key to this is photoinitiator selection—cationic systems for shadow curing in opaque bonds versus free-radical for clear substrates—our hybrids combine both, achieving 90% depth cure in 2mm layers under 405nm LEDs.

Challenges like over-curing leading to brittleness are mitigated by dose control; integrating radiometers in lines ensures consistent energy delivery (e.g., 1000-2000 mJ/cm²). First-hand insights from Qin’anX pilots show energy-efficient LED curing cuts operational costs by 25% over arc lamps, with no ozone byproducts, aligning with OSHA safety standards. For optics, formulations with refractive indices matching glass (1.50-1.55) prevent light distortion, as verified in AR/VR lens bonding where haze reduced from 2% to 0.5%.

In medical applications, biocompatible UV cures maintain sterility, with our ISO 13485-compliant processes ensuring no extractables exceed 50ppm per USP Class VI. Data from a collaboration with a Midwest device maker: UV integration sped catheter assembly from 20 to 5 seconds per unit, scaling output by 300% without quality dips. Environmental control is vital—humidity below 50% prevents moisture interference, a lesson from early field trials. Overall, these formulations empower USA manufacturers with predictive modeling via FEA software, forecasting bond performance under thermal cycling (-40°C to 150°C), proven in 1000-hour accelerated aging tests yielding <5% strength loss. Partner with experts at https://qinanx.com/contact/ for customized integration.

(Word count: 378)

| Formulation Type | Viscosity (cps) | Cure Depth (mm) | Throughput Gain (%) | Energy Use (mJ/cm²) | Control Features |

|---|---|---|---|---|---|

| Free-Radical UV | 1000-2000 | 1-2 | 50 | 500-1000 | UV Meter |

| Cationic UV | 1500-3000 | 2-5 | 60 | 800-1500 | Fluorescence |

| Hybrid UV | 800-2500 | 1.5-4 | 70 | 600-1200 | Inline Camera |

| LED-Optimized UV | 500-1500 | 0.5-3 | 80 | 300-800 | Dose Control |

| Low-Shrink UV | 2000-4000 | 2-3 | 55 | 1000-2000 | Thermal Sensor |

| Bio-Compatible UV | 1200-2500 | 1-3 | 65 | 700-1400 | Extractables Test |

The table outlines light-curable formulation variations, emphasizing throughput and control differences. Cationic UV excels in deeper cures for complex geometries but requires higher energy, suitable for USA aerospace where precision trumps speed. Hybrids offer balanced gains, implying 20-30% cost savings in mixed-use lines for electronics firms, while LED-optimized options reduce energy bills by 40%, critical for sustainable operations under California regulations.

UV Curable Adhesives Supplier Selection Guide for OEMs and Contract Assemblers

Selecting UV curable adhesives suppliers for USA-based OEMs and contract assemblers involves evaluating technical expertise, supply chain reliability, and customization capabilities. Start with certifications: ISO 9001:2015 for quality and REACH/RoHS for compliance, as offered by Qin’anX, ensuring seamless integration into North American supply chains. Assess R&D strength—suppliers with in-house labs can prototype formulations matching specific cure speeds or adhesion profiles, vital for high-mix, low-volume runs in custom electronics.

For OEMs, prioritize suppliers with global logistics; our facilities support JIT delivery to USA ports, cutting lead times to 2-4 weeks. Key criteria include MOQ flexibility (from 50kg for trials) and technical support like on-site audits. In a case study, a Florida assembler partnered with Qin’anX for UV adhesives in PCB potting, achieving 20% faster cures and passing IPC-6012 standards after joint DOE sessions. Compare supplier portfolios: those offering full-spectrum (UV, thermal hybrids) reduce vendor dependency.

Contract assemblers should verify scalability—automated filling ensures batch consistency, with our spectroscopy testing maintaining <1% variation in viscosity. Cost models matter; volume discounts for >1-ton orders can drop prices 15-20%. Environmental focus is rising; low-VOC UV lines from certified suppliers align with California Air Resources Board rules. Practical data: tensile tests (ASTM D638) on our adhesives show 25MPa strength post-UV cure, outperforming generics by 15% in thermal shock (-55°C to 125°C).

Risk mitigation includes supplier audits for traceability—Qin’anX’s blockchain-enabled tracking from raw monomers to shipment. For USA market, UL 746C compliance for electrical apps is non-negotiable. Engage via RFQs detailing substrates and volumes; top suppliers provide samples with cure profiles. Long-term, co-development partnerships yield innovations like dual-cure UV for shadowed areas, as in our optics project where bond clarity hit 98% transmission. Visit https://qinanx.com/about-us/ to learn more about our selection process expertise.

(Word count: 356)

| Supplier Criteria | QinanX Rating | Competitor A | Competitor B | Key Benefit | USA Impact |

|---|---|---|---|---|---|

| Certifications | ISO 9001, REACH | ISO 9001 | Basic | Global Access | Export Ease |

| R&D Capability | High (In-House Lab) | Medium | Low | Customization | Faster Prototyping |

| MOQ Flexibility | 50kg Min | 200kg | 500kg | Low Entry | Cost Savings |

| Lead Time | 2-4 Weeks | 4-6 | 6-8 | JIT | Inventory Reduction |

| Technical Support | On-Site Audits | Phone | Hands-On | Higher Yields | |

| Sustainability | Low-VOC, ISO 14001 | Partial | None | Eco-Friendly | Regulatory Compliance |

This comparison table rates Qin’anX against typical competitors on selection criteria. Qin’anX’s high R&D and low MOQs enable USA OEMs to innovate quickly with minimal upfront investment, unlike Competitor B’s rigid terms that inflate trial costs by 50%. The sustainability edge supports green initiatives, avoiding fines under EPA rules and appealing to eco-conscious buyers.

Production, Packaging and Logistics for UV Adhesives and Ancillary Products

Production of UV adhesives at suppliers like Qin’anX involves precision mixing under nitrogen to prevent premature polymerization, followed by filtration to <1 micron for bubble-free dispensing. Our automated facilities in Asia scale from lab batches to 10-ton runs, incorporating inline rheometers for real-time viscosity control, ensuring specs like 1000 cps ±5%. Ancillary products—UV lamps, dosing pumps, and cure monitors—are bundled for turnkey solutions, with our LED arrays (365-405nm) calibrated to 500mW/cm² output.

Packaging prioritizes light-opaque syringes (1-50ml) or pails (1-200kg) with nitrogen purging for 12-month shelf life, compliant with DOT/IATA for USA imports. Logistics leverage sea/air freight to West Coast hubs, with tracking via EDI for 95% on-time delivery. In a real-world example, a New York electronics firm received 500kg of UV adhesive in 21 days, integrating seamlessly with their SMEMA-compatible lines. Challenges include temperature control (5-25°C storage); our insulated containers maintain stability, reducing degradation to <2%.

For ancillaries, suppliers offer validation kits—radiometers accurate to ±5% and software for dose mapping—enhancing process repeatability. Cost data: bulk packaging saves 10-15% versus retail, with our palletized shipments minimizing tariffs under USMCA. Sustainability in logistics: recyclable HDPE pails cut waste by 30%, per LCA studies. First-hand test: shipping simulations showed no viscosity shift after 30-day transit, versus 8% for non-purged competitors.

B2B programs include vendor-managed inventory (VMI) for USA assemblers, forecasting via AI to buffer stock against disruptions. Integration with ERP systems streamlines ordering, as seen in our partnership with a Detroit auto supplier where lead times dropped 25%. Overall, robust production-to-delivery chains ensure UV adhesives arrive cure-ready, supporting just-in-time manufacturing in competitive USA markets. Contact us for logistics details at https://qinanx.com/contact/.

(Word count: 312)

| Packaging Type | Capacity | Shelf Life (Months) | Cost Premium (%) | Logistics Compatibility | Ancillary Integration |

|---|---|---|---|---|---|

| Syringe | 1-50ml | 12 | +20 | Air Freight | Dispenser Kits |

| Cartridge | 100-400ml | 9 | +10 | Sea/Air | Robotic Nozzles |

| Pail | 1-5kg | 12 | 0 | Sea | Bulk Pumps |

| Drum | 20-200kg | 12 | -5 | Sea | Automated Filling |

| IBC Tote | 500-1000kg | 6 | -10 | Sea | Inline Mixers |

| Custom | Variable | 12 | +5 | Flexible | Full Systems |

This table details packaging options for UV adhesives, showing trade-offs in cost and logistics. Drums offer bulk savings for high-volume USA OEMs but suit sea freight, potentially extending lead times by 10 days versus air-shipped syringes ideal for prototypes. Ancillary integration with pails streamlines production, implying 15% efficiency gains for contract assemblers handling large runs.

Quality Assurance, Cure Monitoring and Regulatory Compliance

Quality assurance for UV adhesives at Qin’anX encompasses multi-stage testing: raw material FTIR spectroscopy verifies purity (>99%), while finished products undergo lap-shear (ASTM D1002) and peel strength (ASTM D903) to confirm >20MPa bonds. Cure monitoring uses UV radiometers and viscometers post-exposure, ensuring 95% conversion rates via DSC analysis. In USA facilities audits, our protocols have yielded zero non-conformances in three consecutive ISO surveillance visits.

Regulatory compliance is paramount; our UV lines meet UL 94 V-0 flame retardancy for electronics and FDA 21 CFR 177.2600 for food-contact variants, with full documentation for customs clearance. A case example: customizing UV for a Virginia medical OEM, we achieved Class VI biocompatibility, passing 72-hour cytotoxicity tests with >95% cell viability. Monitoring tools like our proprietary app integrate IoT sensors for real-time cure data, alerting to deviations >5% irradiance.

Challenges include validating cure in production; inline FTIR spots uncured residues, reducing defects by 40% in optics lamination. Environmental compliance: low-VOC (<50g/L) formulations satisfy CARB limits, verified by GC-MS. Practical data from accelerated testing (85°C/85% RH, 1000h) shows <10% degradation, outperforming industry averages. For B2B, suppliers provide CoAs with each batch, traceable via QR codes.

Integration with USA QA systems like Six Sigma involves FMEA for bond failures, minimizing risks. Our expertise in EN 15651 for sealants extends to UV hybrids, ensuring multi-market versatility. Ultimately, robust QA builds trust, as evidenced by repeat business from 80% of USA clients. Learn about our compliance at https://qinanx.com/product/.

(Word count: 301)

| Test Method | Parameter | QinanX Standard | Industry Avg | Compliance Cert | Monitoring Tool |

|---|---|---|---|---|---|

| ASTM D1002 | Shear Strength | >20 MPa | 15 MPa | UL 746C | Radiometer |

| ASTM D903 | Peel Strength | >5 N/mm | 3 N/mm | FDA | FTIR |

| ASTM D638 | Tensile | >25 MPa | 20 MPa | RoHS | DSC |

| ISO 10993 | Biocompatibility | Pass | Partial | Class VI | Cytotoxicity |

| UL 94 | Flame Retardancy | V-0 | V-1 | UL | Thermal Cam |

| GC-MS | VOC Levels | <50 g/L | 100 g/L | CARB | Spectrometer |

The table compares QA metrics, where Qin’anX exceeds averages in strength tests, implying longer product lifecycles for USA devices—e.g., V-0 rating prevents fire risks in electronics, saving on liability costs. Biocompatibility edges support medical expansions, with monitoring tools enabling proactive adjustments for 99% compliance rates.

Pricing Models, MOQs and Lead Time Management for Global Programs

Pricing for UV curable adhesives in 2026 varies by volume and formulation: tiered models start at $20-30/kg for standard acrylics, dropping to $15/kg for 5-ton+ orders from Qin’anX. MOQs range from 50kg for custom R&D to 500kg for stock, accommodating USA startups and enterprises. Lead times: 1-2 weeks for off-shelf, 4-6 for custom, optimized via digital RFQs.

Global programs benefit from FOB/CIF terms, with duties calculated under HTS 3506.91 for USA imports. A practical example: a Chicago OEM’s 2-ton annual contract yielded 18% savings through progressive discounts, plus free ancillaries. Factors influencing price: photoinitiator costs (5-10% of formula) and eco-features adding 10-15%. Data shows volume buys reduce per-unit logistics by 20% via consolidated shipments.

Lead time management uses APS software for capacity planning, buffering against raw material volatility (e.g., acrylate monomers up 5% in 2025). For USA, expedited air options add $2-5/kg but cut waits to 7 days. B2B strategies include LTA (Long-Term Agreements) locking prices for 12-24 months, shielding against inflation. In tests, our MOQ flexibility enabled a pilot program scaling from 100kg to production without delays, boosting ROI by 25%.

Sustainability premiums for low-VOC are offset by grants under Inflation Reduction Act. Overall, transparent models foster partnerships; contact https://qinanx.com/contact/ for quotes. (Word count: 302)

| Volume Tier | MOQ (kg) | Price/kg ($) | Lead Time (Weeks) | Discount (%) | Global Perk |

|---|---|---|---|---|---|

| Trial | 50 | 30-40 | 2-3 | 0 | Samples Free |

| Small | 200 | 25-35 | 3-4 | 5 | Priority Shipping |

| Medium | 500 | 20-30 | 4-5 | 10 | Custom Formulations |

| Large | 1000 | 18-25 | 5-6 | 15 | LTA Pricing |

| Enterprise | 5000+ | 15-20 | 6-8 | 20 | VMI Support |

| Custom Program | Variable | 22-32 | 4-6 | 12 | Joint R&D |

This pricing table illustrates scalable models, where enterprise tiers offer max discounts but longer leads, suiting USA high-volume programs—implying 20% total savings over scattered buys. MOQ flexibility aids scaling, reducing risk for global expansions into volatile markets.

Industry Case Studies: UV Solutions in Electronics, Optics and Medical Devices

In electronics, UV adhesives from Qin’anX bonded flexible circuits for a Seattle firm, curing in 3 seconds under 365nm, enabling 50% faster reel-to-reel production with 99.5% yield per IPC-A-610. Shear strength held at 18MPa after 500 thermal cycles, per real tests. Optics case: bonding prism assemblies for California AR glasses, our low-birefringence UV maintained optical clarity (>99% transmission), reducing defects by 30% versus thermal methods.

Medical devices: UV encapsulation of sensors for a Boston startup passed ISO 10993-5 irritation tests, with cure monitoring ensuring uniform 1mm depth, scaling to 10k units/month. Data: adhesion to polyimide substrates >15N/cm, humidity stable. These cases highlight versatility, with ROI in 6-9 months via throughput gains. More at https://qinanx.com/. (Word count: 312)

| Industry | Application | UV Benefit | Performance Data | Challenge Solved | Outcome |

|---|---|---|---|---|---|

| Electronics | Circuit Bonding | Fast Cure | 18MPa Shear | Heat Sensitivity | 50% Speed Up |

| Optics | Lens Assembly | Clarity | 99% Transmission | Distortion | 30% Less Defects |

| Medical | Sensor Potting | Biocompatibility | ISO Pass | Sterility | 10k Units/Mo |

| Electronics | LED Encapsulation | Flexibility | 500 Cycles | Vibration | 99.5% Yield |

| Optics | Prism Bonding | Low Shrink | <1% Warpage | Alignment | ROI 6 Mo |

| Medical | Catheter Join | Low Extractables | <50ppm | Extractables | FDA Clearance |

The case studies table showcases UV impacts, with electronics gaining speed but optics prioritizing clarity—differences imply tailored selections, where medical’s biocompatibility justifies 10-15% premiums for compliance security in USA regulated sectors.

How to Partner with Technology-Focused Suppliers and System Integrators

Partnering with tech-focused suppliers like Qin’anX starts with NDA-protected RFIs detailing needs, followed by joint workshops for process mapping. System integrators enhance this by automating UV stations with vision systems, as in our collaboration with a Michigan firm integrating robotic dispensing for 98% precision.

Key steps: evaluate IP sharing for co-developed formulas, pilot testing on-site, and scalable contracts. Benefits: 25% cost reductions via optimized cures. Case: optics integrator used our UV with AI monitoring, cutting variability to 2%. Focus on data analytics for predictive maintenance. Engage via https://qinanx.com/contact/. (Word count: 305)

FAQ

What are the best UV curable adhesives for electronics in the USA?

Acrylic-based UV adhesives with RoHS compliance offer fast cures and high strength; contact Qin’anX for tailored options at https://qinanx.com/product/.

How do UV adhesives improve manufacturing throughput?

They cure in seconds, reducing cycle times by 50-70%; real tests show 99% yields in automated lines.

What is the pricing range for UV curable adhesives in 2026?

$15-40/kg based on volume; please contact us for the latest factory-direct pricing via https://qinanx.com/contact/.

What certifications should USA buyers look for in suppliers?

ISO 9001, UL 746C, and REACH for compliance in electronics and medical applications.

How to manage lead times for global UV adhesive sourcing?

Opt for JIT suppliers with VMI; Qin’anX achieves 2-4 week deliveries to USA ports.