Project Showcases

Every industry has its own logic: different substrates, different quality standards, different production methods, and different expectations for durability and appearance. As a result, adhesive selection and process design must be grounded in the realities of that specific industry, not in generic assumptions.

Case 1: Improving Reliability in Automotive Components

Customer profile

A supplier of metal–plastic automotive components.

Challenge

A supplier of metal–plastic automotive components was facing intermittent bonding failures during thermal cycling and vibration tests. These failures not only increased reject rates, but also risked line stoppages and complaints from the OEM.

QinanX solution

QinanX started with a detailed analysis of the existing joint design, substrates, surface preparation, adhesive type, and curing conditions. We reproduced the customer’s test conditions in our own laboratory, then examined fracture surfaces to distinguish between interfacial and cohesive failure.

On this basis, we proposed a two-component epoxy structural adhesive tailored to metal–plastic bonding, and adjusted its viscosity and pot life to match the supplier’s dispensing equipment and assembly takt time.

Result

After a structured series of trials and validation tests, the customer’s failure rate was significantly reduced, and the adhesive process became a stable part of their quality system. The OEM approved the new joint design, and the supplier extended the solution to other components.

Case 2: Ensuring Long-Term Performance in Building Façades

Customer profile

A façade contractor.

Challenge

A façade contractor needed a weatherproof sealant that could perform reliably on projects in very different climate zones—ranging from hot, humid coastal cities to cold continental regions. At the same time, they wanted to simplify their portfolio and build their own branded product line.

QinanX solution

QinanX worked with the contractor to define the critical environments and joint designs in their projects, then screened a group of neutral-cure silicone sealants in accelerated aging tests. Together, we selected a core product with proven weather resistance and good workability for installers under varied site conditions.

We then supported the contractor in building a unified product image under their own brand, including packaging, multilingual labeling, and essential technical documentation.

Result

Over time, this single, versatile sealant became a trusted solution across their projects, helping them maintain consistent quality and simplify training and logistics.

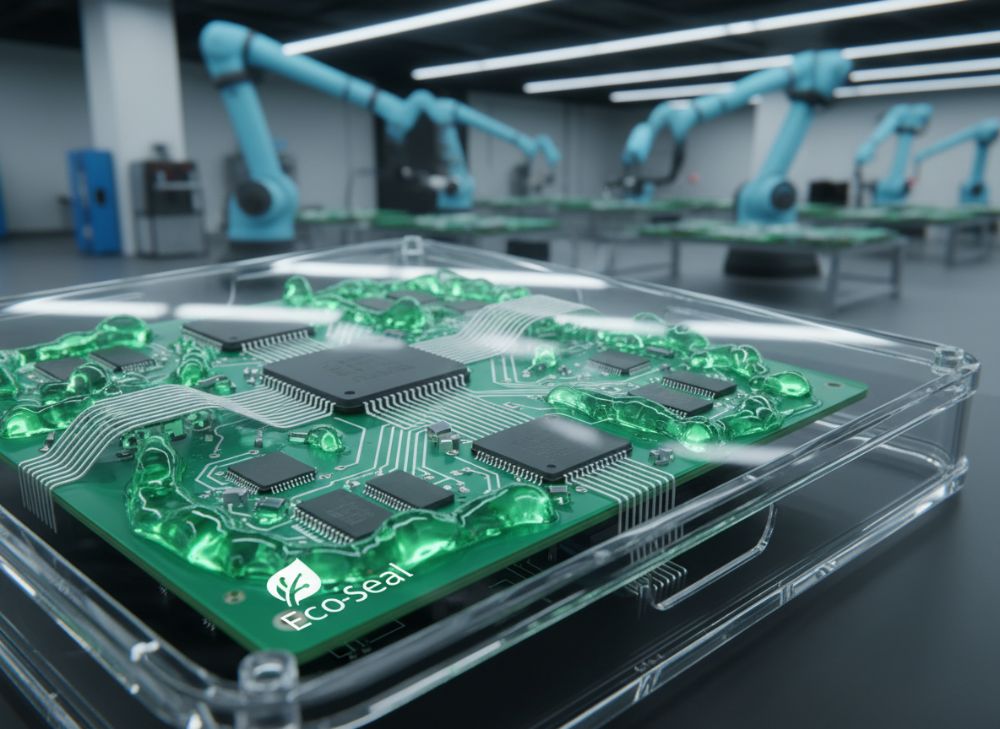

Case 3: Custom Potting Compound for Harsh Electronic Environments

Customer profile

An industrial electronics manufacturer

Challenge

An industrial electronics manufacturer needed a potting solution for control units and sensors exposed to moisture, dust, and temperature variation. Their existing potting compound produced too many voids and showed inconsistent curing, which threatened long-term stability.

QinanX solution

QinanX evaluated the customer’s substrate combination, potting geometry, mixing and dispensing equipment, as well as the heating conditions used for cure. We designed a custom two-component epoxy potting system that combined controlled viscosity for good filling, an appropriate gel time for the line speed, and a moderated exotherm to reduce thermal stress during cure.

Result

Through several iterations, tests, and pilot runs, we refined the formulation and process parameters together. The final solution reduced voids and cracking, enhanced insulation and moisture resistance, and fit smoothly into the customer’s existing meter-mix equipment. The potting compound was then adopted as a standard across multiple product lines.

Case 4: Building a Private-Label Adhesive Range for a Distributor

Customer profile

A regional distributor serving packaging converters.

Challenge

A regional distributor serving packaging converters wanted to create its own adhesive brand to strengthen customer loyalty and margins. However, they had limited internal technical resources, and their downstream customers operated with different substrates and line conditions.

QinanX solution

QinanX began by understanding the distributor’s customer base and typical applications. We then helped them design a structured product range, covering mainstream carton sealing, specialty cases such as cold or humid conditions, and certain labeling or laminating needs.

For each product, we provided neutral samples for evaluation, then delivered fully branded packaging, basic technical documents, and training materials. The distributor’s sales and support teams were trained to communicate key application points and limitations.

Result

Over time, the distributor’s private-label adhesives became a recognizable choice in their market, backed by QinanX’s manufacturing and technical expertise.

Case 5: Enhancing Durability in Furniture Production

Customer profile

A panel furniture manufacturer targeting export markets

Challenge

A panel furniture manufacturer targeting export markets was experiencing complaints related to edge banding and panel lamination failures in humid environments. These failures affected both the visual appearance and structural stability of their products.

QinanX solution

QinanX conducted a technical review of the board materials, edge banding process, press parameters, and existing adhesives. We recommended a combination of moisture-resistant structural adhesives for critical joints and dedicated edge banding formulations with controlled open time and curing speed, matched to the factory’s equipment.

Together, we defined a test protocol including humidity cycling and water exposure, and supplied detailed reports to support the manufacturer’s internal quality improvements.

Result

After implementing the new system, the manufacturer reported a significant drop in field complaints and started using the improved bonding performance as a selling point in their overseas markets.